At Cryometrix, we understand just how pivotal it is to maintain the highest quality in plasma storage and processing. Our state-of-the-art liquid nitrogen (LN2) blast freezers have been engineered to address the most pressing challenges facing blood banks, research laboratories, and biopharmaceutical companies. By harnessing the power of LN2, we help your facility preserve crucial factors in plasma—such as clotting agents, proteins, and enzymes—while maximizing workflow efficiency. In this article, we explain why LN2 technology is revolutionizing the field of plasma freezing and how our B-90 and MB-90 freezers can make a significant difference in your operations.

Why Rapid Plasma Freezing Matters

Plasma contains numerous sensitive biological components that form the backbone of many therapeutic procedures, diagnostic tests, and research initiatives. These include clotting factors vital for patients with coagulopathies, immunoglobulins necessary for immunotherapies, and other proteins that degrade if they are not frozen quickly and uniformly.

Traditional mechanical freezers can struggle to reach ultra-low temperatures in a short span, often requiring extended pre-cooling times. When plasma is exposed to suboptimal freezing rates, unwanted molecular changes may occur, such as protein denaturation and ice crystal formation that can damage cells. With LN2 blast freezers, it is possible to reach -80°C or -90°C in just minutes, thereby improving throughput while mitigating the risk of compromised plasma integrity.

Beyond the biological necessity of rapid freezing, many facilities are pressed for time. High-volume operations in blood banks depend on seamless processing to meet growing demand, and research organizations value quick turnaround to keep critical experiments on schedule. LN2 freezers address these issues head-on by shortening each freezing cycle, helping staff maintain a swift, reliable workflow.

Our LN2 Freezing Technology: How It Works

Compressor-Free Operation

Most cryogenic or ultra-low temperature systems on the market use compressors with refrigerant-based cooling—methods that come with drawbacks like mechanical complexity, potential refrigerant leaks, and high electricity usage. In contrast, Cryometrix LN2 freezers (including the B-90 and MB-90) do away with bulky compressors altogether. Instead, they rely on liquid nitrogen, which undergoes a phase change at extremely low temperatures.

Because LN2 is already at cryogenic levels, less energy is needed to draw the system down to target temperatures. In practice, this means fewer moving parts in your freezer, reduced maintenance needs, and a far simpler design that benefits long-term reliability. What’s more, LN2-based systems typically recover temperature quickly if the freezer door is opened, allowing staff to retrieve or load plasma samples without extensive downtime.

High-Flow Air Circulation

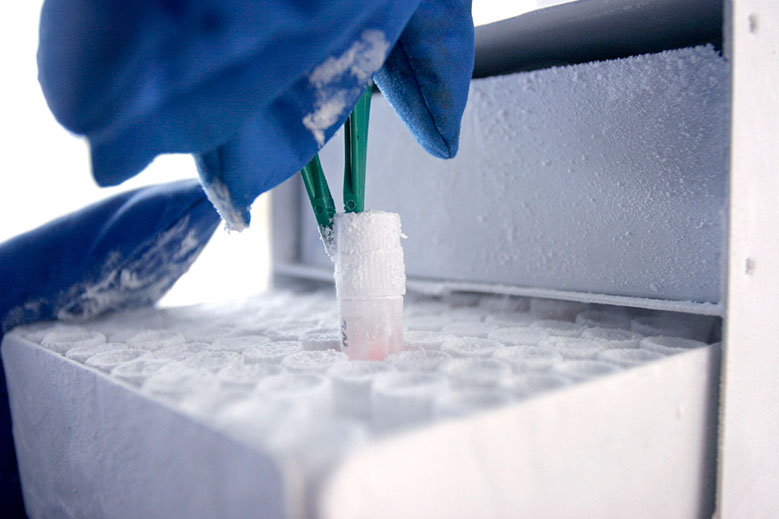

In addition to the inherent cooling power of liquid nitrogen, Cryometrix freezers feature robust circulation fans that move cold air throughout the chamber. This high airflow is crucial for temperature uniformity. When every corner of the payload bay is chilled evenly, plasma samples freeze at a consistent rate, improving the integrity of each unit. By distributing LN2-cooled air more effectively, our systems help prevent hot or cold spots that can degrade sample quality.

Extended Temperature Range

Cryometrix LN2 freezers, including our B-90 and MB-90 models, can operate between ambient temperatures and -90°C. This flexibility caters to a wide variety of applications, from deep-freezing plasma to mild chill settings. Moreover, a wide temperature range enables built-in thawing functions in many models, allowing you to use the same system to warm plasma units up to 40°C if required. This dual capability reduces equipment clutter in labs and opens the door to more efficient freeze-thaw cycles.

How Cryometrix LN2 Freezers Benefit Your Plasma Operations

Faster Throughput

One of the primary advantages of LN2 technology is the dramatically reduced pull-down time compared to mechanical freezers. Mechanical systems might take hours to reach -80°C or -90°C from room temperature, whereas LN2 freezers can often do so in under 10 minutes. For instance:

- B-90 Blast Freezer: Our B-90 model, an upright system, can achieve -90°C from 20°C in as little as 10 minutes. This efficiency is especially valuable in high-throughput settings like large blood banks, where rapid turnover is crucial. In fact, one major American blood bank validated the B-90 and saw an 800% increase in throughput, replacing two large mechanical freezers with just a single B-90.

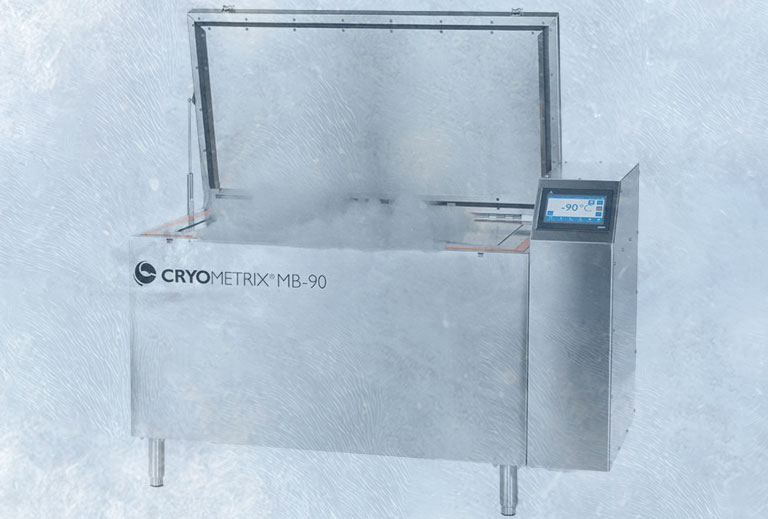

- MB-90 Blast Freezer: Our MB-90 is a chest-style freezer that reaches -90°C from ambient in approximately three minutes. Its quick pull-down makes it ideal for small-batch operations, pilot projects, or research settings where timelines are tight.

Faster freezing translates to more cycles per shift, freeing staff to complete additional tasks. By optimizing your workflow, you can handle a larger volume of high-quality plasma within the same timeframe—something that can vastly improve overall operational efficiency.

Increased Energy Efficiency

Mechanical freezers rely heavily on compressors, which can be energy-intensive, especially at ultra-low temperatures. LN2 freezers operate primarily on the pressure and inherent cold of liquid nitrogen. Though there is some electrical draw for fans, controllers, and possibly defrost systems, LN2 units generally require much less power overall.

This more efficient use of energy helps cut monthly utility costs for labs and hospitals. LN2 freezers generate very little heat, too, alleviating the load on facility HVAC systems. In short, labs can not only save on electricity but also reduce their cooling overhead for the freezer room—another cost benefit of adopting LN2 technology.

Simplified Maintenance

By eliminating compressors, condenser coils, and complex refrigeration circuits, Cryometrix LN2 freezers drastically reduce the number of parts that can fail over time. Mechanical breakdowns, refrigerant leaks, and the associated repairs can cost both time and money. Fewer moving parts means less wear and tear—ultimately translating into higher uptime and more predictable operational expenses.

Scheduled maintenance often involves checks on fan performance, cleaning interior components, and verifying LN2 connections, but does not typically require the detailed troubleshooting of mechanical compressor systems. For busy facilities, minimizing downtime is essential for meeting daily plasma processing demands.

Uniform, High-Quality Freezes

Our freezers incorporate a set of powerful fans that circulate LN2-cooled air at a high velocity, preserving tight temperature uniformity within the payload bay. This uniform environment is crucial for consistency: if different regions of the chamber freeze faster or slower, plasma quality can be compromised.

With LN2 freezers, you get a more stable temperature distribution, ensuring that every plasma unit is exposed to the same freeze conditions. This consistency helps maintain high-quality plasma, which is especially important for therapeutic applications, where controlled freezing directly impacts patient safety and treatment efficacy.

Environmentally Responsible Operation

Nitrogen makes up about 78% of our atmosphere, so liquid nitrogen can be considered a sustainable, readily available resource. Once the LN2 in our freezers evaporates, it simply returns to the air, releasing no harmful chlorofluorocarbons (CFCs) or hydrofluorocarbons (HCFCs). This approach sharply contrasts with mechanical freezers, which often rely on synthetic refrigerants that may have a considerable environmental footprint if leaked.

In addition, quieter operation (compared to compressor-based systems) and a cleaner exhaust (pure nitrogen gas) help foster a safer, more pleasant work environment. If you’re looking to meet sustainability goals or green initiatives, LN2 freezers offer a substantial advantage over conventional ultralow-temperature equipment.

Choosing the Right Cryometrix Freezer

Footprint and Workflow Considerations

Cryometrix offers both upright and chest designs, each optimized for different lab layouts and throughput requirements. For those needing easy access to large volumes, the B-90 upright is ideal. Its vertical orientation provides ergonomic access to plasma samples, and the door design lends itself to quick loading and retrieval. By contrast, the MB-90 is more compact, making it easy to place in smaller labs or tight corners without sacrificing LN2-based performance.

Compliance and Monitoring

We recognize the importance of data integrity, especially for blood products governed by stringent regulations. Our freezers can be outfitted with built-in data logging, touchscreen interfaces, and secure user authentication to help you meet standards such as 21 CFR Part 11. Recorded parameters can include temperature, alarms, door openings, and user logs. This level of detail not only proves invaluable for audit purposes but also allows you to spot process anomalies and rectify them immediately.

Freeze-Thaw Flexibility

Plasma often needs to be thawed for use, and storing separate equipment for freezing and thawing can increase both costs and floor space demands. Cryometrix freezers can handle both freezing and thawing in a single unit, thanks to temperature ranges that can go from -90°C up to +40°C. Adjust your setpoint, confirm the new parameters, and the system will handle the rest—streamlining operations and improving process efficiency.

Robust Safety and Redundancy

Safety remains a core focus for us. Cryometrix systems feature closed LN2 circuits, which protect operators from direct contact with liquid nitrogen while also preventing LN2 from contacting stored plasma. Redundant LN2 valves and emergency override functions provide extra assurance in case of power outages or unexpected facility malfunctions. Alarms are integrated to alert staff of any deviations, such as temperature fluctuations or door ajar events. This holistic safety framework keeps both your team and inventory safeguarde.

Solid Warranties and Support

We design our LN2 blast freezers for longevity, offering warranty periods of up to 20 years on specific cooling components. Our technical support team stands ready to assist you through installation, system upgrades, and routine maintenance. Since LN2 technology involves fewer mechanical parts, many common repairs are quicker and more straightforward, leading to less downtime and smoother overall operations.

Looking Ahead: Future Trends in Plasma Freezing

As the demand for high-quality plasma rises—driven by an aging population, advancements in transfusion medicine, and cutting-edge research—facilities will be pressed to improve freezing capabilities further. We anticipate continued developments in LN2 technology focusing on:

- Even Faster Pull-Down Times – Ongoing refinement of LN2 pathway designs and fan configurations will aim to cut freezing durations to mere moments.

- Higher Levels of Automation – Automated loading systems, remote controls, and AI-driven predictive maintenance may soon become standard features.

- Advanced Data Integration – Expect deeper integration with laboratory information management systems (LIMS) and supervisory control and data acquisition (SCADA) networks, making real-time freezer data easily accessible.

- Modular Configurations – Future LN2 solutions could be more modular, allowing facilities to mix and match capacity and thawing capabilities in the same or interconnected units.

Through in-house R&D and feedback from our users, Cryometrix remains committed to setting new benchmarks in LN2 freezer technology. We continually explore options for boosting throughput, improving temperature controls, and refining data-logging solutions to keep pace with evolving regulatory requirements.

Shaping the Future of Plasma Freezing

At Cryometrix, our mission is to deliver reliable, efficient, and forward-thinking LN2 blast freezers that enhance plasma freezing across multiple industries. By eliminating compressors, focusing on robust internal design, and leveraging clean, naturally abundant liquid nitrogen, we help protect product integrity, maintain regulatory compliance, and boost throughput.

Whether you opt for the B-90 Upright Blast Freezer—ideal for fast processing of high volumes—or the MB-90 Compact Chest Freezer—suited to smaller spaces and swift freeze cycles—you can trust in Cryometrix systems to drive better results in plasma handling. We stand by the quality of our designs through comprehensive warranties and dedicated support, ensuring your investment remains valuable for years to come.

Contact us today to learn how Cryometrix LN2 freezers can optimize your plasma freezing operations, foster sustainable practices, and elevate the overall efficiency of your lab or production facility. Together, we can reshape what’s possible in plasma processing, laying the foundation for safer, more effective therapeutic products and groundbreaking research.