In the modern biopharmaceutical landscape, ultra-low-temperature (ULT) storage is a cornerstone of successful research, process development, and drug manufacturing. Sensitive biological samples—including cell lines, proteins, enzymes, and “seed” materials—must remain consistently below -70°C or -80°C to preserve their integrity and viability. Historically, compressor-based freezers met this need. Yet these systems often use excessive energy, generate heat that places a burden on HVAC systems, and suffer mechanical failures that can stretch over weeks.

To resolve these challenges, the Cryometrix T-90 freezer employs liquid nitrogen (LN2) cooling to maintain stable -80°C storage with fewer moving parts, lower energy consumption, and minimal environmental impact. In a recent large-scale implementation, a biopharma facility replaced twenty-five mechanical units with just twelve T-90 freezers, achieving immediate savings, improved reliability, and a short return on investment (ROI). This article explores the advantages of switching to LN2-based technology for long-term biopharma storage solutions, highlighting energy savings, environmental benefits, and enhanced uptime.

Why Switch From Compressor-Based to T-90 LN2 Freezers?

1. Sustainability and Greener Operations

Biopharma organizations across the globe are under pressure to reduce their carbon footprints and demonstrate environmental responsibility. A key advantage of T-90 freezers lies in their reliance on nitrogen, which makes up more than 75% of Earth’s atmosphere. By replacing synthetic refrigerants (often linked to greenhouse gas emissions) with LN2, the T-90 freezer significantly lessens environmental impact.

Energy usage is also curtailed. Mechanical freezers run noisy compressors that work around the clock, producing large amounts of heat and driving up electricity demands. These compressors require powerful HVAC systems to maintain comfortable ambient temperatures, creating a secondary source of high energy consumption. In contrast, the T-90 freezer’s LN2 system expends considerably less electricity; the natural cooling properties of liquid nitrogen drive the temperature down without relying on energy-intensive hardware. Reducing heat output further cuts strain on air-conditioning systems, aligning well with corporate sustainability goals and helping facilities meet stringent environmental standards.

2. Reliability and Minimal Downtime

A second major motivator for switching is the enhanced reliability of LN2-based freezers. Mechanical freezers feature numerous moving parts—motors, compressors, pumps, refrigerant lines, and other components—which can fail or degrade over time. Repairs for these issues can take weeks, leading to unplanned downtime that puts valuable samples at risk.

Because the T-90 leverages LN2, it contains fewer components that can malfunction. When properly maintained, liquid nitrogen systems exhibit a much lower failure rate compared to traditional refrigeration setups. To underscore this point, Cryometrix offers a 20-year warranty on the T-90 freezer’s cooling system. This extensive warranty protects labs from having to replace or significantly repair equipment after only a few years of operation, ensuring minimal interruptions to critical research, development, and manufacturing processes. Reduced downtime not only secures the integrity of stored materials but also eases budgetary pressures related to emergency repairs, equipment rental, or product loss.

3. Significant Cost Savings

Beyond sustainability and reliability, many organizations find that LN2 freezers generate substantial cost savings over their operating life. In the case of the biopharma facility mentioned earlier, reducing twenty-five mechanical freezers to twelve T-90 units resulted in an immediate decrease in utility bills. The streamlined LN2 design means each T-90 consumes less energy and alleviates the load on facility HVAC systems, further cutting monthly expenses.

Moreover, the simpler architecture of LN2 systems translates to fewer major repairs and part replacements. With compressor-based freezers, maintenance costs can escalate as machines age, due to the complexity and variety of parts. LN2 freezers also tend to outlive their mechanical counterparts, which frequently require substantial repairs after five or six years of service. By contrast, T-90 freezers remain operational for decades with relatively low upkeep, making them a financially sound choice for organizations looking to optimize total cost of ownership (TCO).

Stable -80°C Storage for Seed Materials

For many drug manufacturing workflows, “seed” materials form the bedrock of production. These materials, which can include cell lines, viral stocks, or genetic constructs, must remain in a carefully controlled environment to retain viability and effectiveness. Any deviation above -70°C or -80°C risks compromising the samples’ integrity—potentially derailing research or delaying product cycles.

The T-90’s liquid nitrogen–based system is well-suited for this mission. Nitrogen boils at -196°C, which allows the T-90 to achieve and maintain -80°C with relative ease. Multiple fans within the freezer distribute cold air uniformly, creating consistent temperatures across shelves and preventing the formation of hot or cold spots. Even when the door is opened to access materials, the T-90 quickly returns to the target temperature—often within about ten minutes. This rapid recovery is vital in active labs, where frequent door openings can otherwise cause harmful temperature swings that degrade samples.

Key Advantages of the T-90 Freezer

Eco-Friendly Cooling

Thanks to its LN2-based design, the T-90 operates free of chemical refrigerants that could harm the environment. Compressor-based freezers typically rely on hydrofluorocarbons (HFCs) or other chemicals linked to global warming. By venting harmless nitrogen gas instead, T-90 freezers integrate seamlessly into green initiatives. Facilities focused on cutting carbon emissions and shrinking their environmental footprint will find LN2 solutions a practical means to bolster sustainability credentials.

Minimal Maintenance

Mechanical freezers include compressors, condensers, hoses, refrigerant fluids, and oils—all of which can wear out. Unexpected part failures bring labs to a halt, forcing them to move samples to backup units, rent temporary storage, or rush to fix the damaged unit. T-90 freezers bypass much of this complexity. Labs need only monitor LN2 levels, check the valves and lines occasionally, and ensure proper insulation. Fewer components mean fewer repair calls, lower costs, and a greatly reduced chance of losing precious materials during unplanned breakdowns.

No HVAC Burden

Compressor-based freezers generate substantial heat as a byproduct, which must be removed from the storage area using air conditioning and ventilation systems. This requirement can be particularly challenging in large facilities with multiple freezers in a confined space. T-90 freezers, however, do not generate significant heat. As a result, labs can reduce their HVAC load and potentially decrease air-conditioning costs. This advantage is especially meaningful in facilities that run round-the-clock or are located in warmer climates, where cooling costs can be prohibitive.

Small Footprint

The T-90’s upright, stainless-steel design is space-efficient and allows the freezer to be placed against walls or next to other units with minimal clearance. Compressor-based freezers often require additional space around them for airflow and heat dispersion. By consolidating storage into fewer LN2 units, facilities can free up substantial floor space for other essential equipment or additional freezers. In high-value areas where every square foot matters, the T-90’s smaller footprint can make a noticeable difference in layout flexibility.

Rapid Door-Open Recovery

Frequent door openings are common in busy labs, where teams must retrieve or store samples multiple times throughout the day. Every opening introduces warm air that can compromise temperature stability. The T-90’s design brings internal temperatures back to -80°C in about ten minutes, much faster than many mechanical freezers. This rapid return to setpoint reduces temperature excursions that could degrade sensitive cells, enzymes, or proteins, protecting the integrity of research and manufacturing processes.

Practical Considerations for LN2 Freezer Implementation

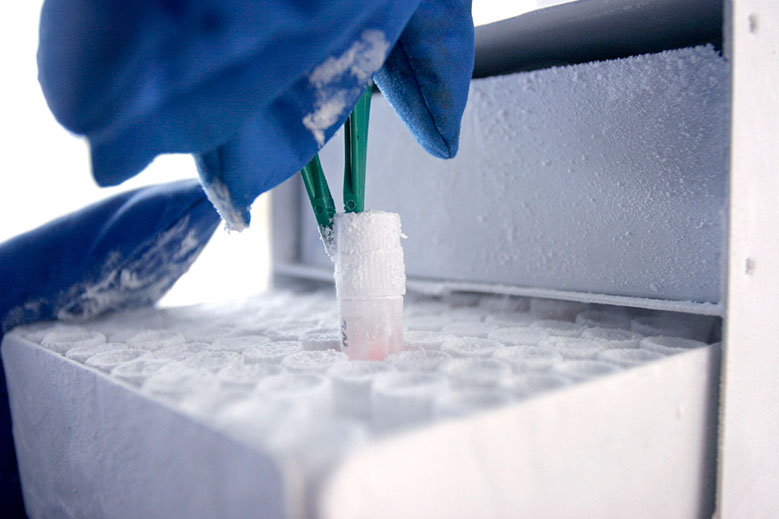

Before upgrading to LN2-based freezers, facility managers typically evaluate a few practical considerations. First, an adequate supply of liquid nitrogen is essential. Labs might need an on-site nitrogen tank or establish a reliable schedule for LN2 deliveries. Second, installation plans should include proper venting to safely disperse extra nitrogen, as high nitrogen concentrations can displace oxygen in poorly ventilated areas.

Staff training is another crucial element. Although LN2 is non-toxic, it is extremely cold and can be hazardous if mishandled. Employees need instruction on using personal protective equipment (PPE), recognizing signs of oxygen displacement, and following standard operating procedures for safe LN2 handling. Finally, data logging and alarm systems—built into the T-90’s controls—help staff monitor freezer performance and rapidly address any deviations from set temperatures.

A Short ROI and a Future-Proof Choice

Whether you are expanding a new facility or upgrading an existing one, the Cryometrix T-90 freezer offers a balanced blend of sustainability, cost-efficiency, and reliable performance. By relying on LN2 cooling, you eliminate many drawbacks of compressor-based systems: excessive energy consumption, frequent maintenance, and long repair times. The facility that replaced twenty-five older units with twelve T-90 freezers is a prime example of the T-90’s strengths—lower utility bills, minimal downtime, reduced maintenance, and robust long-term reliability.

Beyond immediate cost savings, T-90 freezers offer a future-proof solution that can grow with your biopharmaceutical operations. As environmental regulations become stricter and research needs become more complex, LN2 technology provides a path forward that is both dependable and eco-friendly. Quick temperature recovery, uniform cooling, and excellent sample protection ensure compliance and peace of mind for labs managing critical materials.

Learn More

If you are ready to transform your ultra-low-temperature storage, contact us to learn about the T-90 freezer and other LN2-based solutions. Explore product details like data logging, user-friendly touchscreen controls, and temperature uniformity, and see how Cryometrix can help you meet sustainability targets while delivering exceptional sample protection. By choosing LN2, labs and manufacturing facilities alike can reduce power usage, shrink their carbon footprint, and secure the quality of their materials.

About Cryometrix

Cryometrix is a top provider of LN2-based freezer solutions, focusing on sustainable, efficient, and dependable equipment for biopharma storage. From ultra-fast pull-down times to straightforward digital interfaces, Cryometrix freezers are specifically engineered to deliver consistent, ultra-low temperature performance. The company’s 20-year warranty on its cooling systems underscores its commitment to longevity and reliability. By working with Cryometrix, laboratories and manufacturing sites around the world can meet their compliance, environmental, and operational goals—all while safeguarding samples critical to research, development, and large-scale pharmaceutical production.