Ensuring Safe and Efficient Transportation of Biologics

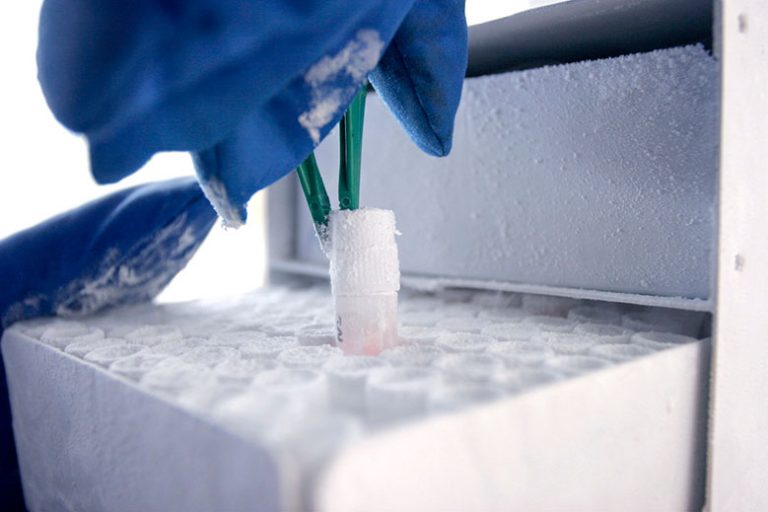

In today’s rapidly evolving pharmaceutical and biotechnology landscape, biologics are complex medications derived from living cells that drive innovation in disease treatment and prevention. However, their sensitivity to environmental conditions presents a significant challenge: maintaining strict temperature control throughout the…