In the rapidly advancing world of cryogenics, the use of liquid nitrogen has revolutionized the process of blast freezing, offering unparalleled speed, efficiency, and safety. Liquid nitrogen, with its extremely low boiling point of -196°C, serves as the backbone of modern cryogenic technology. This innovative approach to blast freezing has found applications across various industries, including biotechnology, pharmaceuticals, and logistics, providing solutions that meet the increasingly stringent requirements for temperature-sensitive products.

The Science Behind Cryogenic Blast Freezing

Cryogenic blast freezing involves the rapid cooling of products to extremely low temperatures using liquid nitrogen. Unlike traditional mechanical freezers that rely on compressors and refrigerants like freon, cryogenic blast freezers use liquid nitrogen to achieve much lower temperatures in a fraction of the time. The efficiency of this process stems from the direct use of liquid nitrogen’s intense cold, which allows for rapid temperature reduction without the need for complex mechanical systems.

The advantages of cryogenic blast freezing are numerous. First, the speed at which products can be frozen is significantly faster—up to eight times quicker than traditional methods. This rapid freezing is critical in industries where maintaining the integrity of sensitive products is paramount. For example, in the pharmaceutical and biotechnology sectors, where the preservation of biological materials like plasma, stem cells, and Car-T cells is essential, cryogenic blast freezing ensures that these materials retain their viability and potency.

Innovations in Cryogenic Technology: The Cryometrix B-90

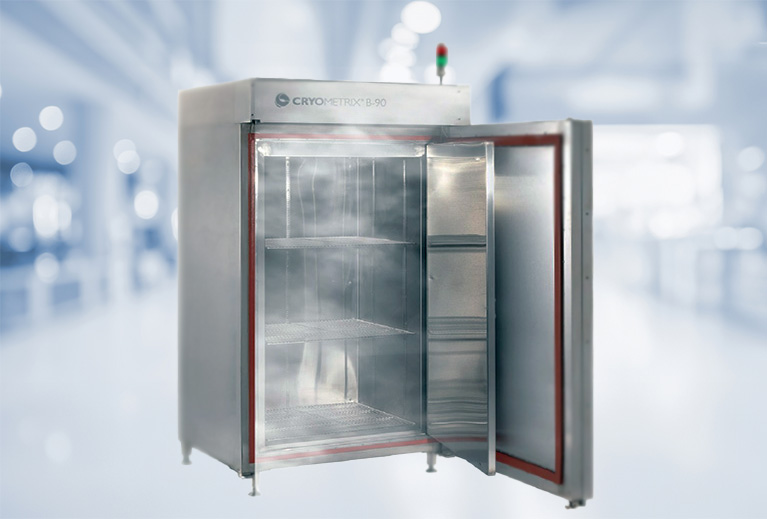

One of the leading innovations in cryogenic blast freezing is the Cryometrix B-90 blast/thaw freezer. This state-of-the-art unit exemplifies the power of liquid nitrogen technology, offering unprecedented freezing capabilities that cater to the high demands of modern industries.

The Cryometrix B-90 can reduce the temperature of its payload bay from 20°C to -90°C in just 10 minutes, making it one of the fastest freezers on the market. This remarkable speed not only increases throughput but also enhances the quality of the frozen products by minimizing the time they spend at intermediate temperatures, where degradation can occur.

The B-90’s design eliminates the need for a traditional compressor, resulting in a simpler, more reliable system with fewer moving parts. This simplicity translates into lower maintenance costs and a significantly longer operational lifespan compared to mechanical freezers. Additionally, because the liquid nitrogen is contained within the system, there is no direct exposure to the operator or the products, ensuring safety and preventing contamination.

Applications Across Industries

Cryogenic blast freezing technology is not limited to a single industry. Its applications are diverse, ranging from advanced medical treatments to logistics and transportation. Here’s a closer look at how different industries benefit from this technology:

Biotechnology and Pharmaceuticals

In the biotechnology and pharmaceutical industries, maintaining the integrity of biological samples during freezing is critical. The Cryometrix B-90 and its compact counterpart, the MB-90, are designed to meet these stringent requirements. These freezers offer precise temperature control and rapid freezing, which are crucial for preserving the viability of cells, tissues, and other biological materials.

For example, Car-T cell therapy, a cutting-edge treatment for cancer, relies on the ability to store cells at ultra-low temperatures without compromising their function. The Cryometrix T-135 Ultra-Low Temperature Freezer, capable of reaching -135°C, is specifically designed for such applications, ensuring that these valuable therapeutic cells remain viable until they are needed.

Logistics and Transportation

Transporting temperature-sensitive products, such as pharmaceuticals and biological samples, requires reliable and consistent temperature control. The Cryometrix S-90 Low Temperature Shipper is a game-changer in this field, offering a self-contained system that can maintain temperatures as low as -80°C for up to 15 days. This level of control ensures that products remain within the required temperature range throughout transit, reducing the risk of spoilage or degradation.

The S-90’s ability to operate without a traditional power source, relying instead on liquid nitrogen’s natural cooling properties, makes it a versatile solution for both ground and air transportation. Whether shipping across the country or internationally, the S-90 provides peace of mind by maintaining the integrity of valuable shipments.

Environmental and Economic Benefits

Cryogenic blast freezing is not only a technological advancement but also an environmentally friendly and cost-effective solution. Traditional mechanical freezers require significant amounts of electricity and often rely on refrigerants that are harmful to the environment. In contrast, cryogenic freezers use liquid nitrogen, which is non-toxic, non-flammable, and abundant in the atmosphere.

The energy efficiency of cryogenic freezers is another significant advantage. For instance, the Cryometrix B-90 uses up to 90% less energy than comparable mechanical freezers, leading to substantial cost savings over time. Additionally, because these freezers do not produce heat during operation, they reduce the need for air conditioning in the surrounding environment, further lowering energy costs.

The Future of Cryogenic Freezing

As industries continue to evolve and demand more from their freezing and storage solutions, cryogenic technology is poised to play an increasingly important role. The innovations in liquid nitrogen-based freezing systems, such as those developed by Cryometrix, are setting new standards for performance, reliability, and safety.

With a commitment to ongoing research and development, companies like Cryometrix are continually improving their products to meet the changing needs of their customers. Whether it’s enhancing the speed and efficiency of blast freezing or developing new applications for cryogenic storage, the future of this technology looks promising.

Looking Ahead: The Future of Cryogenic Freezing Technology

Harnessing the power of liquid nitrogen for cryogenic blast freezing represents a significant leap forward in preserving and protecting temperature-sensitive products. From biotechnology and pharmaceuticals to logistics, the impact of this technology is far-reaching. By offering faster freezing times, better energy efficiency, and enhanced safety, cryogenic blast freezers like the Cryometrix B-90 are not only meeting the demands of today’s industries but also paving the way for future advancements.

As we look to the future, the continued innovation in cryogenic technologies will undoubtedly unlock new possibilities, ensuring that industries can operate more efficiently and sustainably while maintaining the highest standards of quality and safety.