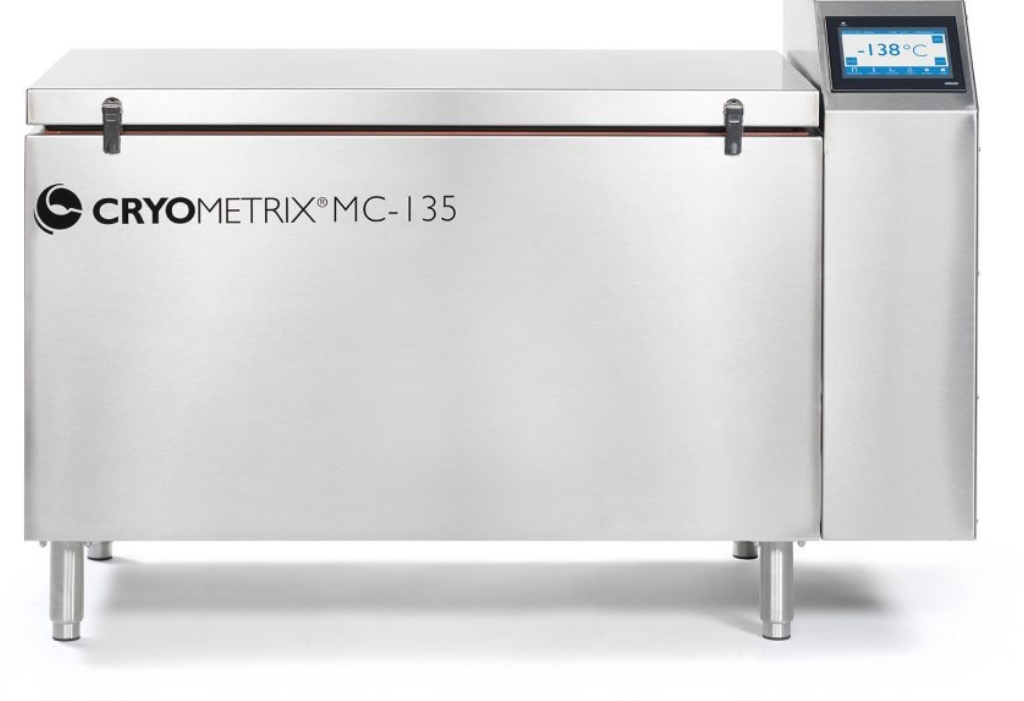

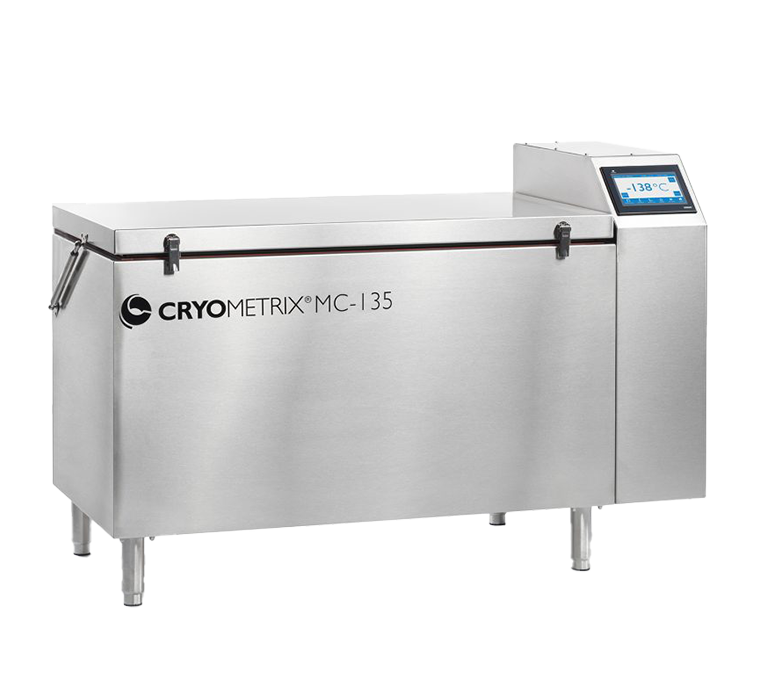

Cryometrix MC-135 Ultra-Low-Temperature Chest Freezer

Compact, Energy-Efficient LN2 Storage to –140 °C for Cell-Therapy, Biobank & Pharmaceutical Workflows

Key Advantages at a Glance

| Benefit | MC-135 Advantage |

|---|---|

| True Ultra-Low Range | Stable 20 °C to –140 °C operation with ± 3 °C uniformity |

| 15-Minute Pull-Down | Reach –135 °C from ambient using only 0.5 gal LN2 per minute |

| Exceptionally Low Power Draw | 4 A at 120 V—about the same as a desktop workstation |

| 20-Year Cooling-System Warranty | Industry-leading coverage for two full decades |

| All-Stainless Construction | cGMP-ready, corrosion-resistant interior and exterior |

| Regulatory Options | CE-marked; optional 21 CFR Part 11 data-integrity package |

| Plug-and-Play Scalability | Low amperage lets you add units without new circuits |

| Closed LN2 Loop | No contact between nitrogen and samples or personnel |

Performance & Engineering Details

Rapid, Repeatable Cooling

- Fast Ramp: An internal LN2 heat exchanger drops the chamber from room temperature (~22 °C) to –135 °C in approximately 15 minutes at 100 psi supply pressure— accelerating GMP manufacturing, cryopreservation, and R&D timelines.

- Door-Open Recovery: After a three-minute lid opening at –135 °C, the freezer rebounds to set-point in six minutes, reducing thermal excursions that can compromise sensitive biologics.

Energy & Infrastructure Savings

- Minimal Electrical Demand: Operating on a standard 120 VAC, 4 A circuit, the MC-135 frees panel capacity for other instruments and simplifies installation in older facilities.

- Lower HVAC Load: Compressor systems dump heat back into the room; the MC-135 absorbs heat while venting cool nitrogen gas, often lowering ambient temperature slightly and easing air-conditioning demand.

- Efficient LN2 Use: Steady-state consumption is roughly 0.7 gal/hr at –80 °C or 1.1 gal/hr at –140 °C, translating to longer intervals between Dewar refills and predictable operating schedules.

Compliance & Data Integrity

- Triple-Level User Control: Up to 100 unique logins can be assigned view-only, operator, or administrator rights, aligning with ISO 13485 and CFR audit expectations.

- Onboard Data Logging: Temperature is sampled every 10 seconds, with door events, alarms, and set-point changes stored in tamper-evident memory. CSV export is available via USB or Ethernet.

- Optional Part 11 Upgrade: Electronic signatures, audit trails, and robust authentication help clients meet FDA 21 CFR Part 11 and EU Annex 11 guidelines without external software.

Comprehensive Technical Specifications

| Category | MC-135 Specification |

|---|---|

| Temperature Range | 20 °C to –140 °C |

| Peak Variation | ± 3 °C |

| Pull-Down (ambient → –135 °C) | 15 min @ 100 psi |

| Door-Open Recovery | 6 min (3 min lid open) |

| Interior Capacity | 4.2 cu ft / 120 L |

| Interior (W×D×H) | 26 × 17 × 16.5 in (660 × 432 × 419 mm) |

| Exterior (W×D×H) | 56.5 × 27 × 39 in (1435 × 686 × 990 mm) |

| Empty Weight | 450 lb (205 kg) |

| Electrical | 120 VAC ±10 %, 60 Hz, 4 A, NEMA 5-20 |

| LN2 Supply Pressure | 30–100 psi |

| LN2 Inlet Fitting | CGA 295 male |

| Construction | 304 stainless steel (inside & out) |

| Certifications | CE-marked; designed & built in the USA |

Application-Specific Benefits

Cell & Gene-Therapy Manufacturing

Autologous and allogeneic therapies often require cryogenic arrest below –120 °C to preserve cellular potency. The MC-135 integrates seamlessly into Grade D cleanrooms, supports rapid batch cycling, and pairs with automated bag-handling systems for closed, GMP-compliant workflows.

mRNA & Lipid-Nanoparticle Drug Substance Storage

Messenger-RNA and LNP formulations show greater long-term stability at temperatures colder than –130 °C. Using the MC-135 minimizes degradation, simplifies logistics, and helps CDMOs maintain product quality throughout quarantine, release, and distribution.

Biobanking & Translational Research

University core facilities storing thousands of tissue sections, serum vials, or DNA samples can consolidate multiple mechanical freezers into fewer MC-135 units, easing electrical loads and creating space for next-generation sequencing or mass-spectrometry instruments.

Veterinary & IVF Clinics

Cryopreservation of embryos, semen, and oocytes demands uniform ultra-low temperatures and zero cross-contamination risk. The MC-135’s closed gas-loop design ensures no liquid LN2 contacts specimens, while the stainless interior simplifies cleaning and regulatory oversight.

Sustainability & Environmental Stewardship

No High-GWP Refrigerants

Mechanical ULT freezers typically use HFC blends with global-warming potentials exceeding 1,300. The MC-135 vents only nitrogen, which has a GWP of zero.

Lower Carbon Footprint

Facilities replacing several mechanical units with MC-135 freezers frequently reduce site-wide electricity consumption for cold storage by more than two-thirds, shrinking indirect CO2 emissions.

Long-Life Construction

With a 20-year warranty and a fully recyclable stainless- steel shell, the MC-135 minimizes equipment turnover and landfill burden.

Operational-Efficiency Summary

| Efficiency Factor | MC-135 Impact |

|---|---|

| Electrical Demand | Up to 90 % lower than mechanical ULTs |

| HVAC Relief | Negligible heat rejection can moderate lab ambient temperatures |

| LN2 Optimization | Intelligent valve modulation reduces consumption during steady- state hold |

| Scalable Expansion | Low-amp draw enables additional units without panel upgrades |

Installation Guidelines & Best Practices

Site Preparation Position the freezer on a level surface rated for 500 lb. No crane or gantry is required; standard pallet jacks suffice.

Ventilation Although nitrogen gas is non-toxic, small rooms should maintain six air changes per hour to prevent oxygen displacement under worst-case conditions.

LN2 Plumbing Use a vacuum-insulated line (1⁄2-inch OD recommended) with minimal bends for optimal flow.

Startup Procedure Power on the controller, set desired temperature, and open the supply valve; the system auto-tunes once the target is reached.

Routine Checks Weekly review of digital logs, monthly gasket inspection for frost build-up, and annual probe validation with a NIST-traceable reference thermometer.

Frequently Asked Questions

How does the freezer perform during a power outage?

LN2 flows by pressure, so cooling continues even without electricity. Manual valves provide backup control, and product held at –135 °C remains within specification for extended periods.

Can the MC-135 operate at warmer set-points?

Yes. Any temperature between +20 °C and –140 °C is programmable, enabling phased protocols for viral clearance, controlled-rate thawing, or crystal-growth studies.

Does liquid nitrogen contact the samples?

No. A closed stainless-steel coil chills circulating nitrogen gas; samples never encounter liquid LN2, eliminating splash risks and simplifying GMP cleaning validation.

What storage devices fit inside?

Standard 2-inch cryoboxes, cryo-racks, stainless-steel baskets, and flat-lay bag dividers are all compatible. Cryometrix offers custom accessories for tubes, plates, and bulk bags.

Service & Support Ecosystem

- Global Parts Distribution — Replacement parts including valves, sensors, and control boards ship from our manufacturing facility in Utah, USA regions around the world.

- Operator Training — Complimentary webinars cover alarm response, preventative maintenance, and regulatory record-keeping.

- Validation Packages — IQ/OQ protocols and chamber mapping services help satisfy GMP and ISO certification requirements.

Future-Proof Your Cold Chain

Personalized medicine, biologics, and mRNA vaccines require storage solutions beyond legacy –80 °C freezers. The Cryometrix MC-135 delivers deeper temperatures, unparalleled energy efficiency, and two decades of reliability—all wrapped in an installation-friendly footprint. Whether you’re scaling a cell-therapy suite, modernizing a hospital biobank, or pursuing sustainability milestones, the MC-135 offers measurable operational gains and unwavering protection for the samples that matter most.