Cryometrix B-90 Blast/Thaw Freezer

Blast freeze your products faster than you ever imagined possible. The Cryometrix B-90 Blast/Thaw Freezer uses patented liquid nitrogen (LN2) technology to reach ultra-low temperatures in a fraction of the time it would take a typical mechanical freezer.

This is far from your ordinary ultra low freezer. The B-90 sets a new standard for efficiency and reliability in blood banking, pharmaceutical, biotechnological, and research environments. Read on to discover how it achieves extreme temperature pull-downs, why it drastically reduces maintenance, and how its built-in thawing feature can simplify your processes.

Ultra-Fast Blast Freezing

Imagine dropping your freezer bay from +20°C to -90°C in about ten minutes — no waiting around for hours like you do with a mechanical system. With the Cryometrix B-90, that’s exactly what you’ll experience thanks to its advanced LN2 blast freezing design. Where compressors and refrigerants often slow you down, the B-90’s efficient engineering delivers:

- Zero Exposure to Liquid Nitrogen for product or personnel.

- Consistent Cooling: Enjoy ±3°C uniformity across the entire payload bay. Your samples, bags, or vials receive the same reliable freeze every time.

- Shorter Downtime: After opening the door, the chamber returns to -80°C or -90°C in about one minute, so you keep your cycles consistent and quick.

If your facility handles large volumes of temperature-sensitive materials—be it blood, plasma, biologics, vaccines, or other critical lab products—the B-90 gives you the power to freeze them at unprecedented speeds, helping optimize your daily workflow and prevent bottlenecks.

Built-In Thawing, No Extra Equipment Needed

The Cryometrix B-90 doesn’t just blast freeze. It also thaws within the same chamber. Take advantage of temperatures up to +40°C to gently warm your stored materials without needing a separate thawing apparatus. Simply adjust the setpoint on the B-90’s intuitive touchscreen and let it do the rest. No more juggling multiple machines or occupying extra floor space just for thaw cycles.

Real-World Validation in Blood Banking

A major American blood bank replaced two large mechanical freezers (plus a rooftop compressor) with a single B-90—and saw an eightfold increase in throughput. By freeing up floor space and eliminating maintenance headaches, the bank kept more units in continuous processing. The B-90:

- Shortened freeze times

- Reduced the downtime traditionally needed to defrost or repair compressors

- Created a quieter, more efficient work environment

This success story demonstrates the dramatic improvements possible when you switch from outdated mechanical systems to the Cryometrix B-90.

Zero Compressors Means Minimal Maintenance

Mechanical freezers rely on compressors, condenser coils, refrigerants, and oil, all of which wear out or fail over time. This design complexity can lead to:

- Unscheduled Downtime

- Expensive Service Calls

- Larger Maintenance Staff Budgets

The Cryometrix B-90 changes the game with an LN2-based cooling system that has very few moving parts. There’s no compressor to worry about, no refrigerant lines to leak, and no complicated recharges. By doing away with compressor systems entirely, you’ll see far fewer breakdowns, lower repair bills, and significantly less operational hassle. Additionally, LN2 is contained within a sealed system, so there’s never direct contact with your samples or your staff.

Say Goodbye to Overheating and High Energy Bills

If you’ve ever stood near a large mechanical ultra low freezer, you know they can throw off substantial heat into the environment. This in turn taxes your HVAC system, drives up energy costs, and makes it harder to expand your lab operations. The B-90 tackles these issues head- on by using pressurized liquid nitrogen instead of compressor-generated cooling:

Lower Power Draw

No hefty compressors running around the clock. The B-90 mainly uses electricity for fans, sensors, and the control system.

Less Ambient Heat

LN2-based cooling does not pump heat into the room, making it easier to maintain comfortable, stable conditions for staff and equipment.

Reduced HVAC Load

Decrease your reliance on heavy-duty air conditioning to offset the heat from compressors, potentially saving on utility bills and future HVAC upgrades.

Scalable Expansion

If you need more capacity, simply add another B-90 without fear of straining your electrical infrastructure. The self-contained LN2 system keeps electrical requirements surprisingly modest.

Data Logging and Security Features

Maintaining a strict chain of temperature control is vital in laboratories that handle precious or regulated materials. The B-90 was designed with state-of-the-art data logging and security capabilities:

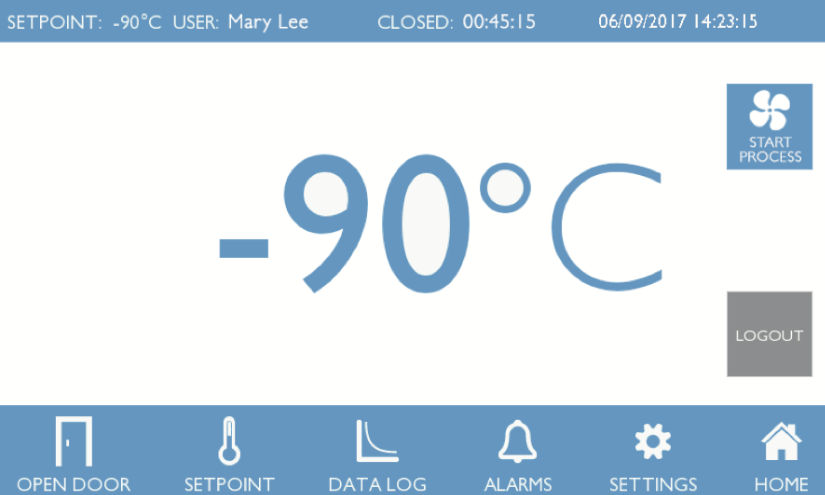

- Touchscreen Interface: Instantly view current temperature, setpoints, logs, alarms, and user permissions.

- Exportable Logs: Download CSV files to your computer or network, making it easy to archive or review temperature data and user actions.

- User Management: Create up to 30 users across three standard security levels to control who can adjust settings or open the door. For labs needing expanded access management, an Industrial PC (IPC) upgrade offers even more user levels.

- Optional IPC upgrade: Upgrade the control package if you operate under FDA-regulated conditions requiring validated electronic records and signatures.

These built-in tools save time, boost accountability, and simplify audits—especially in cGMP environments.

A 20-Year Warranty on the LN2 Cooling System

A strong warranty says a lot about quality and confidence. Cryometrix backs the B-90’s cooling system with a 20-year warranty on parts, reflecting how robust and dependable this LN2 design truly is. Compare that with the shorter warranties typically offered on mechanical freezers, and you’ll quickly see how the B-90 stands apart. With so few mechanical components, failures are inherently less common. But if something does happen to the LN2 cooling system, rest assured you’re covered.

Key Specifications

- Temperature Range: +40°C to -90°C

- Temperature Uniformity: ±3°C across the payload bay

- Exterior Dimensions: ~41.8 in. (D) x 48.2 in. (W) x 94 in. (H)

- Payload Capacity: ~700 liters / 26 cubic feet, with enough space for up to 48 x 5 L bottles

- Pull-Down Speed: ~10 minutes from ambient to -80°C (empty chamber)

- Door Recovery: ~1 minute to return to -80°C after a 3-minute door opening

- Electrical Requirements: 120V–220V, 60 Hz, ~12A, NEMA 5-20 plug

- LN2 Usage: ~1.5 gallons per minute during initial ramp-down, decreasing substantially once target temperature is reached

- Certifications: UL 508a for the electrical panel; CE compliant; optional 21 CFR Part 11 software package

- Warranty: 20 years on the LN2 cooling system (for parts)

Built for Reliability and Operational Safety

Upright Stainless Steel Construction

Access your products without digging through awkward horizontal shelves. The upright design provides a straightforward, ergonomic experience—and the 100% stainless steel interior and

exterior make it easy to sterilize and keep in pristine condition. Plus, stainless steel is corrosion- resistant, so you can count on it lasting for the long haul.

LN2 Redundancy

If something unexpected happens, redundant LN2 valves help maintain the proper temperature. This is especially beneficial if you’re storing large volumes of critical plasma, reagents, or other samples that cannot tolerate a temperature excursion.

Optional Battery Backup

Worried about power outages? The B-90 offers an optional battery backup that can keep essential functions—like temperature monitoring and fans—operating for up to three hours. In combination with LN2’s natural insulation benefits, you’ll have extra protection for your stored items during unexpected power disruptions.

Streamlined Footprint

Whether you’re running a small research lab or a large biopharmaceutical facility, floor space matters. The B-90’s upright design, minimal external hardware, and minimal side clearance requirements make it surprisingly easy to integrate into existing layouts. You only need about six inches of space to allow for door swing. If you decide to add additional B-90 units in the future, you won’t need extensive restructuring of your lab.

Increase Your Productivity

Unmatched Pull-Down

No more sitting idle while you wait on a mechanical system to reach ultra low temperatures.

Rapid Door Recovery

Frequent openings? Not a problem—the B-90 rebounds to set temperatures almost immediately.

Two-in-One Freezing and Thawing

Whether you need to get materials to -80°C or warm them back to +40°C, just adjust the setpoint.

Fewer Service Interruptions

A compressor-free design cuts maintenance visits, so you stay on schedule.

Proven Scaling

If your operation grows, simply add more B-90s without the high electrical demands or the need for extra compressors.

Frequently Asked Questions

How safe is liquid nitrogen?

LN2 is non-toxic, non-flammable, and commonly used in labs, clinics, and research facilities. The Cryometrix B-90 is designed with a sealed LN2 system, so there’s no direct exposure to the product or the user. Any gaseous nitrogen simply vents into the atmosphere, which is already composed mostly of nitrogen.

What if the power goes out?

The B-90’s LN2-based approach helps maintain cold temperatures even when electrical power is briefly lost. An optional battery backup can run core functions, like fans and the control system, for up to three hours. Redundant valves also help stabilize temperatures during emergencies.

How do I arrange LN2 supply?

You’ll need a pressurized LN2 source at ~100–125 psi, which is standard in many labs. Cryometrix can guide you on sourcing LN2 tanks or setting up the right infrastructure for your volume needs.

What about compliance with FDA guidelines?

An optional 21 CFR Part 11 package is available for facilities needing strict electronic records and signature compliance. You’ll get features like tamper-proof audit trails, user-specific login credentials, and more.

How often does the LN2 system require servicing?

With few moving parts and no compressors, the B-90 has a drastically lower service burden. You might periodically check connections and ensure your LN2 supply meets pressure requirements, but you won’t be dealing with refrigerant leaks or compressor failures.

Experience the Cryometrix B-90 Difference

The Cryometrix B-90 Blast/Thaw Freezer has redefined what’s possible in ultra low temperature freezing, bringing you fast blast cycles, efficient thawing, and dramatically lower maintenance. By harnessing LN2’s natural advantages instead of relying on conventional compressors and refrigerants, the B-90 delivers quiet, dependable, and eco-friendly performance day in and day out.

If you’re ready to move beyond the limitations of mechanical freezers and join the next generation of rapid blast-freezing technology, reach out to Cryometrix. Our team will help you find the right setup, guide you on LN2 logistics, and show you exactly how to maximize throughput. With a proven track record and a 20-year warranty on the cooling system, the B-90 is more than just a great freezer—it’s a long-term investment in your lab’s efficiency and success.